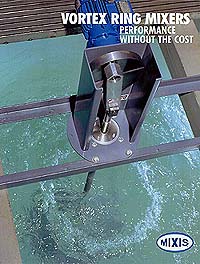

Vortex Ring Mixers (VRMs) are the logical result of the realization that frequent production of vortex rings in a controlled manner will result in an efficient homogeneous mixing process. They were invented and developed by Dr. Latto as a highly efficient alternative to conventional fluid mixers.

VRMs generate vortex rings by the controlled ejection of fluid through an orifice, located either in a reciprocating impeller or stationary tube. The distance a vortex ring travels, the region being agitated and the energy consumption can be controlled which, in turn, affects the mixing process. A vortex ring mixer, therefore, has many applications.

The principle forms of VRMs are reciprocating orifice plates and pulsed tubes. The selection of a particular form of mixer depends on a number of considerations, such as automatic fluid or solid addition, gasification, sedimentary nature of the fluid, accessibility of the mixer to the mixing vessel geometry, depth of fluid, etc. The tube type mixers are usually non-intrusive and can be fitted outside a mixing vessel.

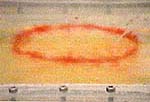

The energy consumed to generate a vortex ring is stored within the rotating toroid of fluid and is gradually dissapated as the ring progresses through the bulk of the fluid. Thus the energy input to the fluid in achieving a homogeneous mixing process is consumed primarily in the transport process and not undue turbulence and excessive shearing.

The energy consumed to generate a vortex ring is stored within the rotating toroid of fluid and is gradually dissapated as the ring progresses through the bulk of the fluid. Thus the energy input to the fluid in achieving a homogeneous mixing process is consumed primarily in the transport process and not undue turbulence and excessive shearing.

- Extremely low energy consumption

- Rapid homogeneous mixing

- Low shear

- No vessel buffers or baffles required

- Can be used in tall tanks and with various tank aspect ratios

- Excellent for sedimentary and floating materials suspension

- Easy to control

- Usually easy to retrofit

- Low Maintenance

- Savings on operating costs

- Freedom of vessel geometry

- Low capital cost

- Improved process control

- Unique application

D. Weaver & Associates are looking for representation throughout our coverage area We will respond to ANY inquiries in ANY area.

For further information about Mixis Vortex Ring Mixers use the electronic form available here, or contact:

1344 WILKSHIRE CIRCLE SW

NORTH CANTON, OH 44720

OFFICE: (330) 499-1779

FAX: (330) 499-0916

Email info@dwaassoc.com

RETURN TO HOME PAGE